Custom Blister Packaging

Custom Blister packaging is ideal for small consumer goods. This type of plastic packaging highlights the product and provides a degree of tamper resistance while still being easy to open. Clear, plastic blisters are cost-effective, high visibility, clean, and protective packaging solutions for the retail, electronics, industrial, consumer goods and medical applications. Blisters in combination with paper backer cards can be manufactured from a wide variety of resins based on the application, proposed function and product size. Common blister materials – PET, PVC, GPETG and PETG. For sustainable solutions, recycled content and even bio-based materials are available.

Custom Blister Packaging Features

- One piece of custom-formed plastic sheet

- Used in conjunction with specially manufactured paperboard to complete the package

- Blister can be trapped between two pieces of paperboard to make a trapped blister

- Blister can be affixed to a single piece of paperboard

- Blister is held in place using heat and pressure to activate an adhesive on paperboard

- Incorporate the product’s shape to enhance brand identity

- High-visibility package showcases product

- Designed to be easy to open by hand

- Strong enough to hang on a hook

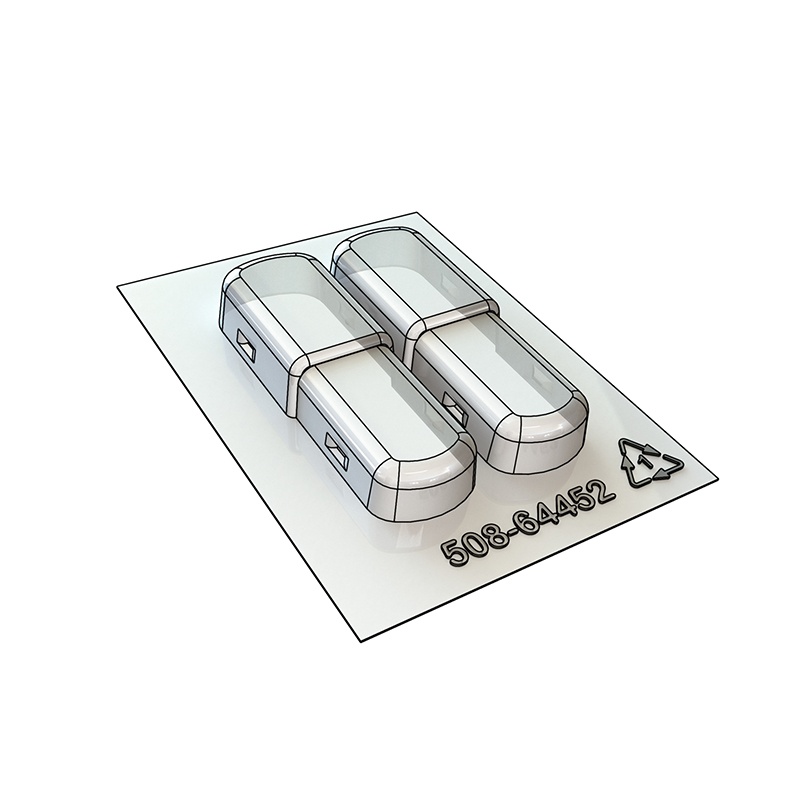

Custom Blister Packaging Description

Blister Types

- Trapped blisters: a blister which is trapped and secured between to blister cards

- Face seal blister: blister which is sealed to the blister card on the flange surface

- Full face seal blister: blister which is sealed to blister card not only on flange surface but other sections of the blister

Flange

- This is a portion of the blister which is located just outside the product cavity

- Minimum flange is required for manufacturability and sealing to or within a blister card or trap blister

- Provides blister structure

- Area can be used to identify product with part number

- Flange can be sealed to a blister card or trapped within “ trapped blister” fold over card

- Top of flange can be used and designed to accept hanger hole placement

Product Cavity

- Specific cavity for retention and containment of packaged product

- Cavity can be custom designed to fit specific product

- Product retention features can be included to reduce product movement within blister

- Cavity can be generic in shape and size if used for multiple items like screws, bolts, nails, etc.

- Product cavity can be positioned on front, back or both blister sections – the latter – would be considered a double blister

Tamper-Evident

- A packaging solution which ensures product integrity.

- A blister is sealed to aqueous coated card

- When blister is removed or attempted to be removed, the blister presents evidence of tampering

- Visible evidence of tampering

Engraved Features

- Text or logo which is engraved on the production tool which will appear on all blisters manufactured.

- Company name and address

- Website address

- Plastic resin code

- Recycle recommendation

- Most fonts and font sizes are available

ABOUT UPPI

UPPI is a worldwide developer, manufacturer and marketer of specialized, custom thermoformed plastic packaging. Our business is the design, creation, and production of effective, yet cost-efficient packaging for the retail, medical, electronics, industrial, and food industries. If you would like to learn more about our services, please do not hesitate to contact us.

- Learn About Us

- Call: (717) 766-1578

- Email: sales@uppi.com